Graphite electrode operation manual

Please carefully read this operating manual before usage, which can really help you use electrode in the right way:

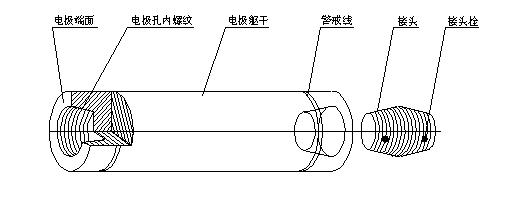

1. Names and Introduction of All Parts of Graphite Electrode

Introduction:

The connector of the graphite electrode is conical-shaped and has two types: one inch three threads (T3) and one inch four threads (T4). The length of the connector also has two types: standard type and lengthened type.

2. Packaging of Graphite Electrode

2-1 Separate Packaging Type

The electrode and the connector are separately packaged and transported.

2-2 Pre-packaging Type

One end of the electrode is connected with the connector, both ends of the electrode are installed with protective caps, and then the electrode is packaged and transported.

The main action of the packaging is to protect the electrode and the connector from being damaged in storage and transportation, particularly protect threads from being damaged.

3. Storage of Graphite Electrode

3-1 The electrode and the connector should be placed on wood, an iron stand or clean cement ground, so that the electrode is prevented from being damaged or contaminated by dust; and for the electrodes which are not used now, their package should be removed, so that the dust and foreign bodies are prevented from falling on the threads, end surfaces of electrode or internal threads of electrode socket;

3-2 The electrode should be placed in order in the warehouse, the ends of the electrode stacks should be well cushioned in order to avoid the electrodes from falling off, and the piling height of the electrodes should not be more than 2m in general;

3-3 The stored electrodes should be kept away from rain and moisture; and the moist electrodes should be dried before using, so that the electrode is prevented from cracking and more oxidation in steel making;

3-4 The connectors of the stored electrodes should not be close to a place at high temperature so as to avoid the melting of the connection pins.

4. Transportation of Graphite Electrode

4-1 When the electrodes are lifted or inversely moved, please pay more attention, gently lift and place the electrodes, so that the electrodes are prevented from tilting to slip off to break the electrodes;

4-2 In order to guarantee that the internal threads of the electrode sockets on the end surfaces of the electrode and the connector threads are under good conditions, do not use iron hooks or other hard materials to hang the electrode sockets or connectors at both ends of the electrodes when the electrodes are lifted, you should use the special electrode hoist to lift the unpackaged electrodes;

4-3 When the connector box is loaded or unloaded, you should gently handle it so as to avoid the bumping of the connectors, which may cause the damage to the threads;

4-4 When the electrodes are lifted up, the end contacting the ground should be cushioned by soft pads so as to avoid damaging the ends and connectors of the electrodes; and for the electrodes with big diameter, you should gradually use mechanical devices for horizontal-vertical switch of the electrodes;

5. Choose a Proper Graphite Electrode

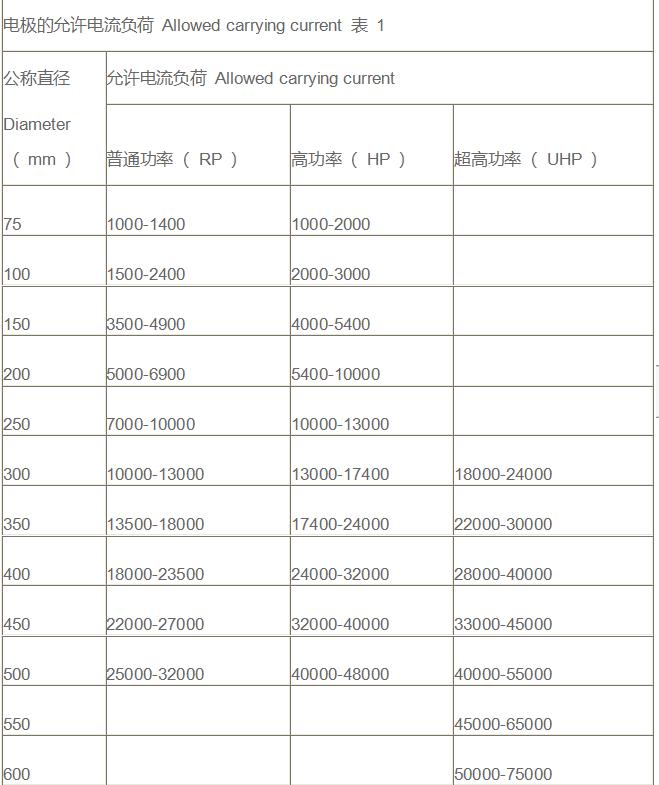

5-1 Please choose a proper electrode grade and electrode diameter according to the capacity of the electric furnace and the transformer, please refer to Table 1:

Table 1 is the allowed current load of the AC electric furnaces, and as for DC electric furnaces, con-steel furnaces or refinery furnaces, the current load can be properly increased by 10%.

5-2 You should consider the following operating factors before choosing the grade and the size of the electrode:

Charging Type

Charging Way

Length of Electrode Pole below Clamp

Distance between Furnace Wall and Electrode

Ratio of Melting Time to Total Heating Time and Tap-Tap Time

Type of Waste Gas Emission System

Oxygen Blast Way and Oxygen Blast Amount

Steel Grade, Flow, Period and Balance of Working Procedures, etc.

6.Cautions in Use of Graphite Electrodes:

6-1 When feeding material is charged in the electric furnace, in order to decrease the bumping of the cave-in feeding material against the electrodes, the big size feeding material should be placed at the bottom of the furnace as much as possible, simultaneously prevent non-conducting materials such as lime from being gathered under the electrodes in large quantity, otherwise the electrification of the electrode is affected and the electrode is easy to break;

6-2 Pay attention to the position of the furnace roof; if the furnace roof is not on a right position, when the electrode are ascended or descended, the electrodes will bump against the furnace roof, so that the electrodes will be damaged, more seriously, the electrodes will be broken; also be careful, steel material bonding in the electrode hole part may lead to the same problem;

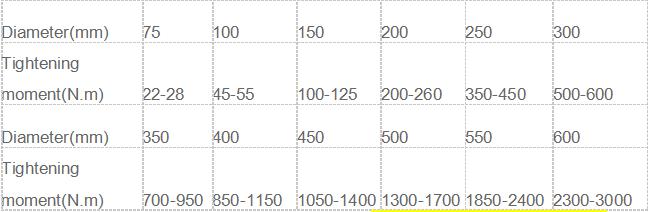

6-3 When the electrodes are connected, blow off ash on the end surfaces and in the sockets of the electrodes by using compressed air, align the connector of the new electrode with the center of the electrode socket, vertically and slowly screw the electrode connector in the electrode socket, and when the connector is screwed in, the applied force should be uniform and steady, and the tightening torque should conform with standards.

Table 2 Tightening moment

6.4 Electrodes that have been joined together should not be laid horizontally so as to avoid broken.

6.5 If any gap exists between end surfaces, it must be removed after finding out the cause.

6.6 When the clamp holds the electrode, please ensure that it is below the safe line and avoid nipping the socket or nipple.

6.7 The electrode should be used vertically and avoid sliding.

6.8 Carbon adding by electrode should be prevented (please use carburant), otherwise performance of electrode will be influenced

6.9 As material and produce process adopted by different manufacturers differ, the physical and chemical properties of the electrodes and nipples differ too. Do not mix use electrodes and nipples produced by different manufacturers.

6.10 Sealing of furnace cover must be good to reduce air coming in. Nozzle and oxygen should be applied properly to reduce oxygen consumption brought by oxidation under high temperature.

6.11 To prevent loose and screw back

1) The phase sequence of 3-phase electrode must be anticlockwise from top

view.

2) Confirm tightening torque is correct.

3) If nipple plug drops off, it must be restored before joining.

4) If new graphite electrode is used for steelmaking for the first time, in order to make the nipple plug heated and coke, please stop cooling water spray.

5) For furnace which vibrates greatly, pin could be used.

6.12 As thread can be classified into T3 and T4, pay attention to use matched lifting plug, nipple and socket.

6.13 In order to reduce consumption, please note that:

(1) Make sure the duration that electrodes stay in furnace as short as possible, and keep proper negative pressure operation in melting furnace, which helps consumption reduction.

(2) Avoid oxygen lance blowing directly to electrodes.

(3) Properly use cooling water.

7 Factors that Influence Consumption of Graphite Electrode

·Feeding amount and method

·Charging time and outage time

·Tap-to-tap cycle

·Exhaust gas emission

·Adjusting on clamper position

·High currency

·Large slag amount

·Improper oxygen blowing

·Operation and joining of electrodes

8 Form of Consumption of Graphite Electrodes

·Sublimation

·Assimilation

·Melt (immerse in furnace hearth)

·Oxidation

·Breakage

Sublimation of arc complies with the function of I2: less graphite electrodes will be consumed by long arc.

9 Cause of Breakage, Tip loss, Butt loss etc

Unusual consumption of electrodes, like breakage, tip loss and butt loss of electrodes, is accidental phenomenon. Causes of such unusual consumption vary, some caused by electrode quality and some by improper operation. When unusual consumption occurs, please contact with after sale service department of Datong carbon/Summit timely, so that both sides can cooperate together to find causes and solve problems.

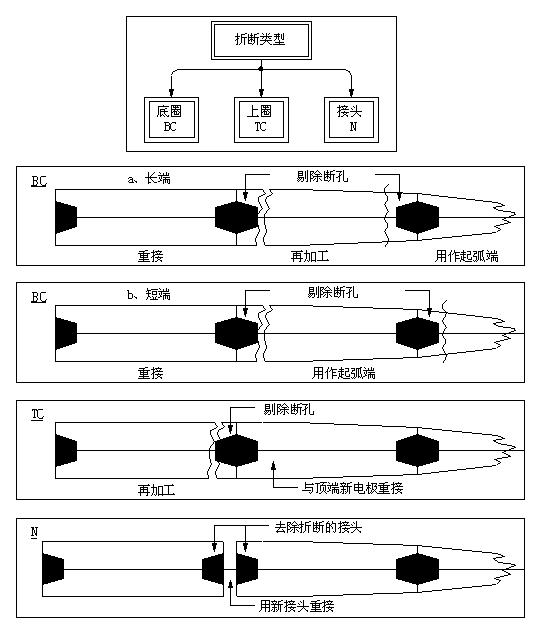

10 Comments on reproduction and re-use of electrodes

The following is the most possible ways to recycle electrodes according to the breakage types. Hammer and chisel could be used to remove the broken electrodesocket. Besides, we suggest to re-machining the broken electrodes in our workshop to the original specifications to obtain the best effect.

11 Electrodes Quality Evaluation

The consumption of each electrode to produce 1 ton qualified molten steel by same equipment under steady condition can be considered as evaluation standard of electrode quality.

12 Applicable object of the instruction

12-1The instruction can be referred by workers in steelmaking plant and project managements.

12-2 For any unreasonable point in the instruction, please revert us with your valuable comments.

12-3 For any dissent or requirements, please contact us by below contacts: