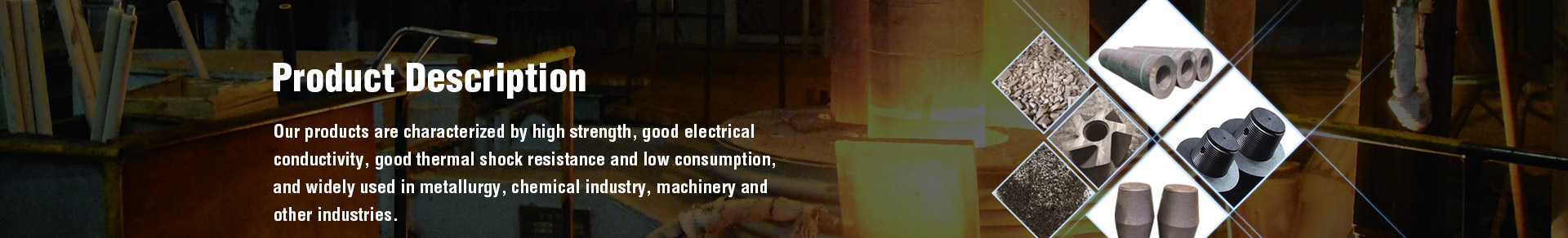

The use of carburizer in the casting process can greatly increase the amount of scrap steel and reduce the amount of pig iron. Most of the recarburizers are now used in electric furnace smelting, and a few recarburizers are particularly fast when used on cupola. Feeding mode for electric furnace melting, should be carburizing agent and scrap steel and other charges together into the surface can choose a small dose of molten iron. However, a large number of carbon should be avoided to add to the molten iron, so as not to oxidize too much and appear the effect of carburization is not obvious, carbon content is insufficient. The amount added is determined according to the proportion of other raw materials and carbon content. All kinds of cast iron, according to the need to choose various types of carburizing agent. Its carburization characteristics of pure carbon containing graphitized material, reduce excessive impurities in pig iron, carburization selection is appropriate, can reduce the production cost of casting.

The use of casting carburizer can not only strengthen the carbon burning loss in the process of steelmaking and ensure the carbon content requirements of special types of steel, but also can be used as an important raw material for post-furnace tempering, as an important raw material for induction furnace melting hot iron, its quality and service status directly affect the use of hot iron.

The role of casting carbonization agent:

Carburizer is a cheap silicon source, carbon source.Using carburizer can prolong the life of furnace wall by 30%The slag source is reduced and the slag removal operation is simple.Rusted waste and alloy can be used to reduce the cost of molten iron.After use can reduce the white mouth, significantly improve the cutting performance, improve mechanical properties.

Adhesion fluidity, stable liquid iron composition, prevent segregation phenomenon.

Reduce the sensitivity of wall thickness, compact structure, smooth cutting surface.

You don't have to worry about aluminum content in molten iron like you do with ferrosilicon.

Don't worry about increasing the sulfur content in molten iron.

The use of carburizer in the casting process can greatly increase the amount of scrap steel, reduce the amount of pig iron or without pig iron, which is characterized by the selection of pure carbon containing graphitized material, reduce the impurities in pig iron, carburizer selection is appropriate, can reduce the cost of casting production.