Resistivity <=5.5,

Bulk Density >=1.69g/cm3,

Ash <=0.3%,

Bending Strength >= 12 Mpa

Elastic Modulus <=8 Gpa

Average Consumption Rate 1.5-2kg

Packing Details:STANDARD PACKAGE IN PALLET.

We're looking for sales agent or business partner of our

product,if you’re interested in, please contact me for pricing and availability.

Please be free to contact

Whatsapp&WeChat No.:+86-13722682542

Web: www.qfcarbon.com

Email: judy@qfcarbon.com

#metallurgy #steelmaking #steelindustry #furnace #steel #fabrication #iron #refractory #metals #mining #casting #metallurgical #engineering #UHP #graphite #electrode

Graphite electrode refers to a kind of high temperature resistant graphite conductive material made with petroleum coke and asphalt coke as aggregate and coal asphalt as binder through the processes of raw material calcination, crushing and grinding, batching, mixing, molding, roasting, impregnation, graphitization and mechanical processing. Mainly used for steelmaking, as well as smelting yellow phosphorus, industrial silicon, abrasives, etc., is in the electric furnace to release electric energy arc situation to heat and melt the charge conductor.

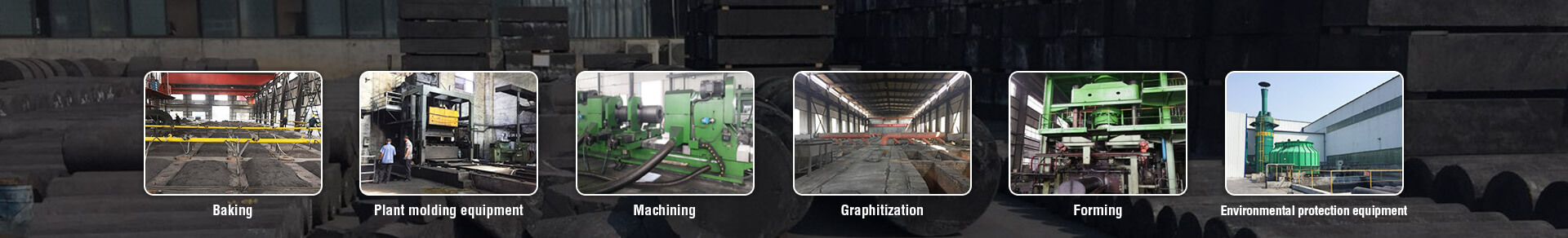

The production process of graphite electrode can be divided into three kinds: pressure vibration method, CNC automatic forming method and mechanical processing method. The main method used in domestic general mold production is mechanical processing method.

According to the national standard, graphite electrode can be divided into ordinary power graphite electrode, high power graphite electrode and ultra high power graphite electrode. There is also a folk model in China, quasi-ultra-high power graphite electrode (SHP), which is a product between high power and ultra-high power graphite electrode, but there is no such model in the actual product classification. The performance is close to that of ultra high power graphite electrode, but the price is lower than ultra high power graphite electrode.

1, ordinary power graphite electrode (RP), allow through the current density is less than 17A/cm2, the raw material is mainly petroleum coke, coal pitch, production cycle is about 45 days, mainly used to refine ordinary steel, silicon and yellow phosphorus, etc.

2, high power graphite electrode (HP), it allows the current density of 18~25A/cm2 between the raw material for petroleum coke, coal pitch, add needle coke, the production cycle is about 60 days, mainly used for steelmaking.

3, ultra high power graphite electrode (UHP), it allows the current density is greater than 25A/cm2, raw materials including petroleum coke, needle coke, coal pitch, the needle coke content is greater than the high power graphite electrode, the production cycle is more than 65 days, used for smelting fine steel, special steel.

The raw material cost accounts for more than 65% of the total graphite electrode cost. The key material of graphite electrode is needle coke. The ultra-high power electrode made of needle coke can shorten the time of steelmaking by 30% ~ 50%, save electricity by 10% ~ 50%, and effectively reduce the cost of steelmaking. One ton of finished UHP graphite electrodes contains 0.85 tons of needle coke, and it takes 1.05 tons of needle coke to produce one ton of UHP graphite electrodes.

The diameter of graphite electrode is 200-700mm, which is difficult to break 700mm due to the limitation of molding machine. The length is generally 1800-3000mm, and the domestic mainstream is 1800-2400mm.

Graphite electrode belongs to the industry of high energy consumption and high emission, the future production expansion may be limited under the background of double high limit. The production of a ton of graphite electrode consumes about 1.69 tons of standard coal, and the carbon emission of a ton of graphite electrode is 4.48 tons according to the conversion method of 2.66 tons of carbon dioxide per ton of standard coal. Therefore, future production expansion may be limited.

Domestic mainstream graphite electrode manufacturers include Fangda carbon, Jilin carbon, Kaifeng carbon, Liaoning Dan carbon, Nantong carbon and so on.